INDUSTRY NEWS

Features and applications of glass bilateral machines

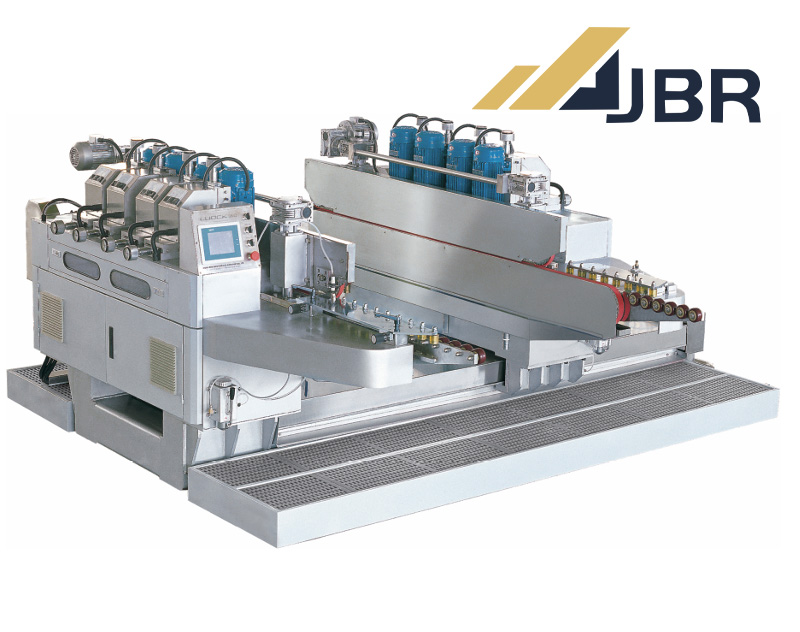

The features of glass bilateral machine include high precision, high efficiency, strong applicability, etc. It is applied in the fields of architectural glass processing, furniture glass production, large glass processing, etc.

Features of glass bilateral machine:

1. High precision:

The double edge machine can handle two opposite sides of the glass at the same time during the grinding process, which ensures the symmetry and consistency of the grinding. This simultaneous grinding greatly reduces the dimensional deviation caused by independent grinding, thus improving the overall processing precision.

The use of an advanced computer control system and precise ball screw drive technology allows for more accurate mechanical operation, further ensuring the high precision required for processing.

The design of the equipment includes an advanced detection and feedback system that monitors the grinding status in real time and automatically adjusts the processing parameters to adapt to minor changes in material properties, ensuring high quality standards for the final product.

2. High efficiency:

The design of the Double Edge machine allows for a fast and continuous production process, dramatically reducing the operating time of traditional single edge grinding. It can process more glass sheets in a shorter period of time, dramatically increasing productivity.

Larger double-edged machines are usually equipped with more grinding heads, such as sixteen, twenty or twenty-two grinding heads, which allows the machine to carry out multiple processes at the same time, such as roughing, finishing and polishing, further enhancing the efficiency and flexibility of production.

With an efficient drive system and optimised operator interface, operators can quickly set up and adjust the machine, which reduces equipment adjustment and waiting time and improves the overall operating efficiency of the production line.

3. Strong applicability:

The double edge machine is not only suitable for straight edge grinding of flat glass, but also can handle various round edges and complex shapes of glass edges, making it widely used in furniture, decoration and special glass production.

Different models of double edging machines are capable of handling glass sheets from small to large sizes, up to a maximum glass size of more than two metres, which makes it possible to meet a wide range of needs from small decorative glass to large architectural glass.

Equipped with PLC control system and variable frequency motor, the advanced double edged machine can adjust the speed and power according to different processing needs, realising diversified processing functions from simple to complex.

4. Advanced technology:

Modern bilateral machine adopts PLC control system to set processing parameters directly through the interface to achieve automatic operation. This control technology reduces human error and ensures the stability and repeatability of the processing.

The use of synchronous belt vacuum suction conveying technology effectively avoids scratches and surface indentation of glass during processing, which is especially suitable for the processing of special materials such as LOW-E glass.

Dynamic balancing system and precise design of mechanical components ensure the stability and durability of the equipment during high-speed operation, reducing maintenance costs and prolonging the service life of the equipment.

Application scope of glass bilateral machine:

1.Architectural glass processing:

Double Edge Machines are widely used to efficiently produce large quantities of straight or rounded edge finished glass required for architectural windows and doors, ensuring that the size and edge finish of each piece of glass meets strict industry standards.

It is suitable for precision processing of large-area glass panels used in high-rise buildings to ensure visual effect and structural safety after installation.

2.Furniture glass production:

In furniture manufacturing, especially where a high quality mirror effect is required, the Double Edge machine provides perfect edge finishing to enhance the aesthetics and practicality of the furniture.

The ability to handle small glass pieces makes the double-edged machine equally suitable for the production of detailed furniture parts, such as cabinet doors or decorative glass.

3. Large glass processing:

For large-scale glass processing companies, the double-edged machine is indispensable, especially in the production of automotive glass and large commercial display glass, where it shows its high efficiency and high quality processing capabilities.

In special applications, such as the production of bullet-proof glass or security glass, the double-edged machine ensures the precise machining of the edges, which is essential to improve the safety of the final product.

4. Decorative and special glass processing:

In the production of art glass, double edgers play an irreplaceable role in enhancing the overall aesthetics and value of the finished product with precise edge finishing.

For decorative glass requiring special edge treatments, such as chamfering, engraving, etc., the double-edged machine can also provide flexible solutions.

In short, the high efficiency and precision of the glass double edging machine and its wide range of applications make it an important piece of equipment in the modern glass processing industry. With the further development of technology, its application areas and efficiency will continue to expand and improve.